Introvert

Elder Lister

You know your brake calipers are due for work or replacement when you experience the following:

The process

Prop the patient on a proper and weight-appropriate jack stand on flat, stable ground.

Use a stack of stones or work with the car on a jack only when you are certain that you’ve had your life’s quota of mind-altering substances.

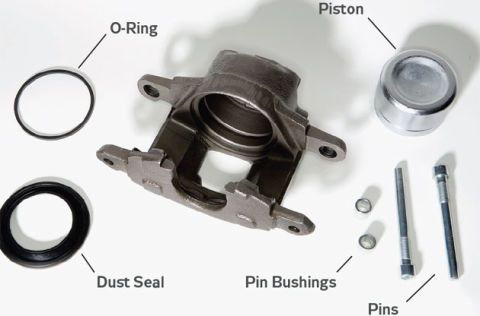

This is what you should find upon taking apart the assembly.

The subject here is a simple model from the 70s.

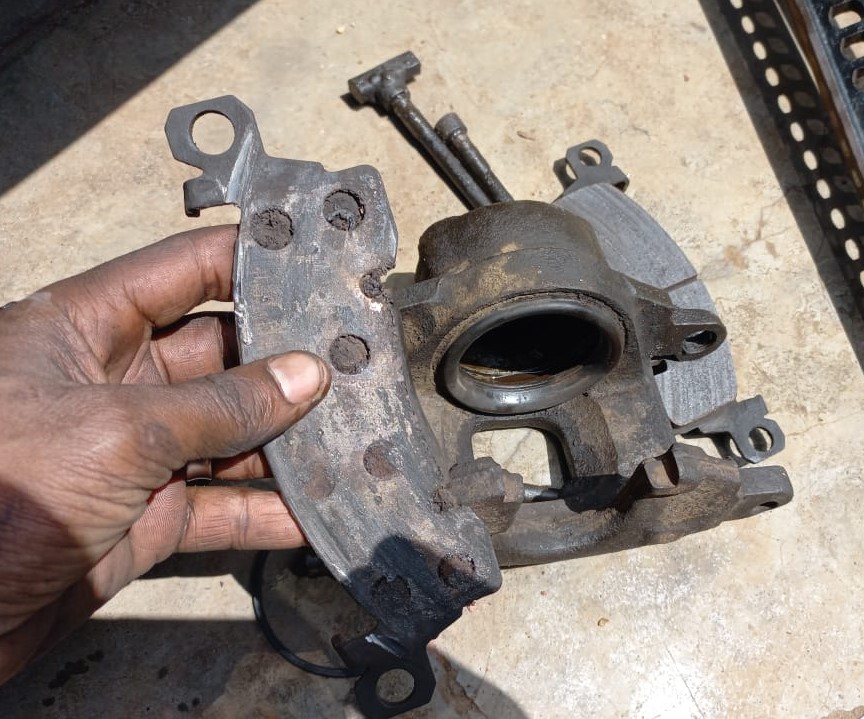

Several things needed correcting here.

1. Torn dust seal.

2. Worn out bleeder bolt losing pressure through gaps in the ill-fitting threads.

3. Scored pistons.

That line of corrosion is one reason why the piston wasn’t traveling proper in the chamber.

4. Worn brake pads.

Remove the fluid seal.

Gently sand the chamber and piston with P600 sandpaper (avoid rougher paper).

I could not find brand new bleeder bolts for this model.

Thank God, though, for the very aptly named Bakisha (a very resourceful hole-in -wall spares shop in Dagoretti Corner) and his bag of non-standard used bolts.

The caliper threads had to be machined on a lathe to make sure they bleeder bolt fits properly.

Perfect fit.

Test by blowing into the nipple. No air should pass through when the bolt is fully tightened.

Clean chamber and all components with brake cleaner spray, fit new O-rings and dust seal and return piston.

Brake pads for this have always an import item so I have them rebonded at Varsani Brake Linings, Industrial Area.

In 2008 the Muhindi sold me a set of brake pads for 200 bob (dead stock from 1981).

What luck!

Fit the assembly and bleed the system.

Disc will be taken for surface skimming later.

Reward self with pure natural apple juice and discuss economic matters with business partner.

- Spongy brake pedal

- Uneven brake pad wear

- Sudden pull to one side when braking

- Fluid leaks inner wheel surface

- Harufu ya burning socks

The process

Prop the patient on a proper and weight-appropriate jack stand on flat, stable ground.

Use a stack of stones or work with the car on a jack only when you are certain that you’ve had your life’s quota of mind-altering substances.

This is what you should find upon taking apart the assembly.

The subject here is a simple model from the 70s.

Several things needed correcting here.

1. Torn dust seal.

2. Worn out bleeder bolt losing pressure through gaps in the ill-fitting threads.

3. Scored pistons.

That line of corrosion is one reason why the piston wasn’t traveling proper in the chamber.

4. Worn brake pads.

Remove the fluid seal.

Gently sand the chamber and piston with P600 sandpaper (avoid rougher paper).

I could not find brand new bleeder bolts for this model.

Thank God, though, for the very aptly named Bakisha (a very resourceful hole-in -wall spares shop in Dagoretti Corner) and his bag of non-standard used bolts.

The caliper threads had to be machined on a lathe to make sure they bleeder bolt fits properly.

Perfect fit.

Test by blowing into the nipple. No air should pass through when the bolt is fully tightened.

Clean chamber and all components with brake cleaner spray, fit new O-rings and dust seal and return piston.

Brake pads for this have always an import item so I have them rebonded at Varsani Brake Linings, Industrial Area.

In 2008 the Muhindi sold me a set of brake pads for 200 bob (dead stock from 1981).

What luck!

Fit the assembly and bleed the system.

Disc will be taken for surface skimming later.

Reward self with pure natural apple juice and discuss economic matters with business partner.